Custom Made

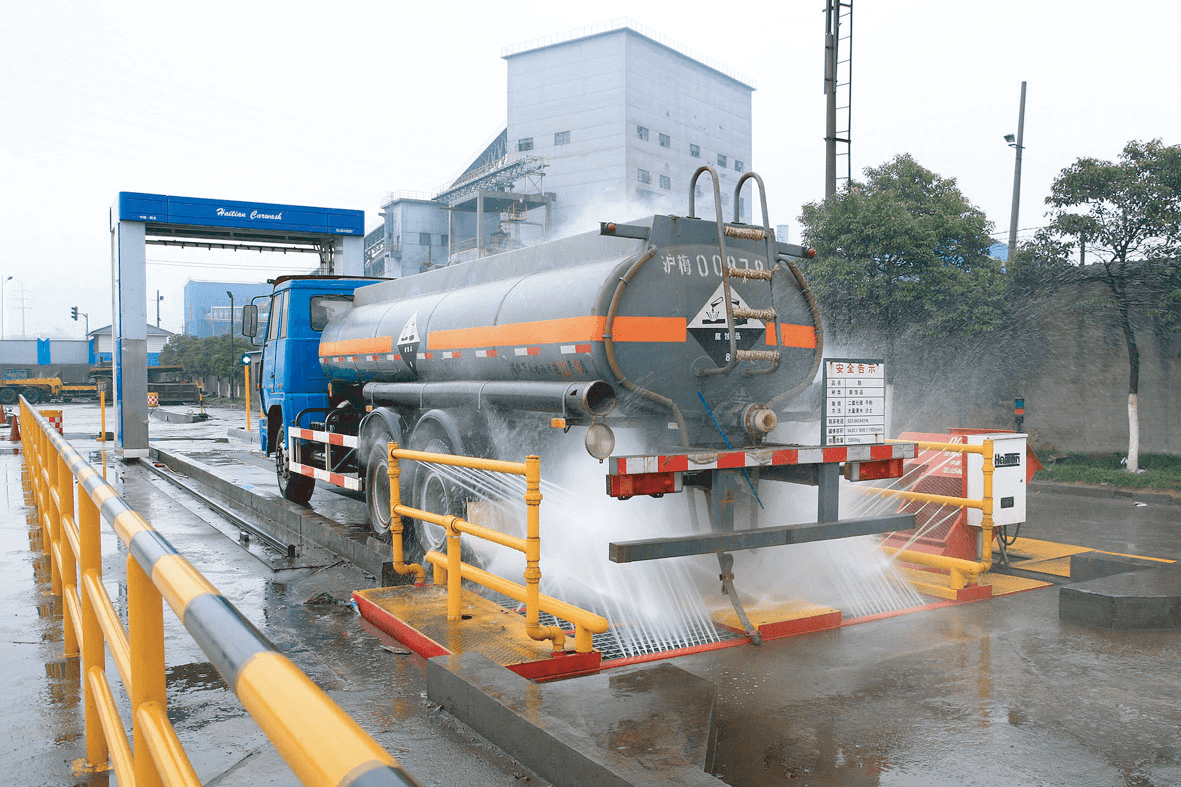

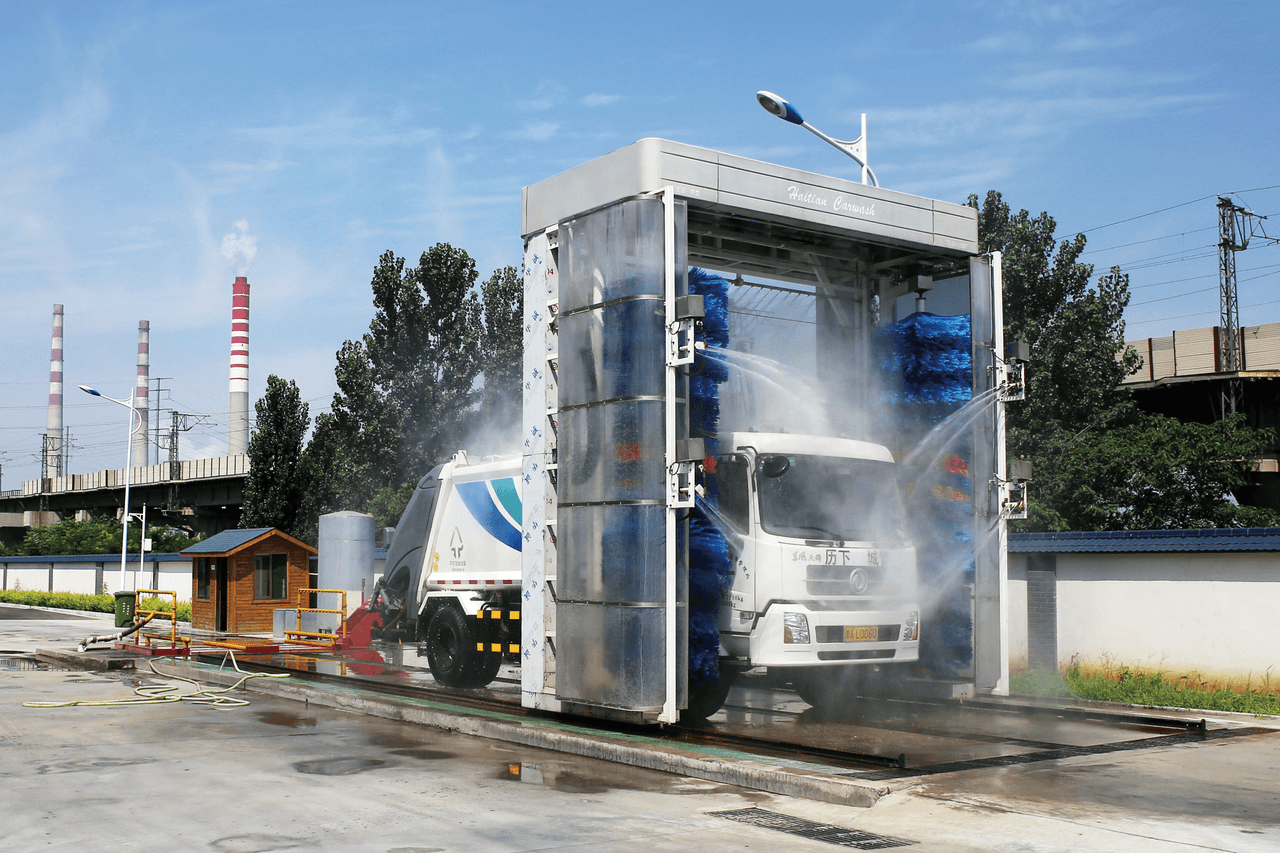

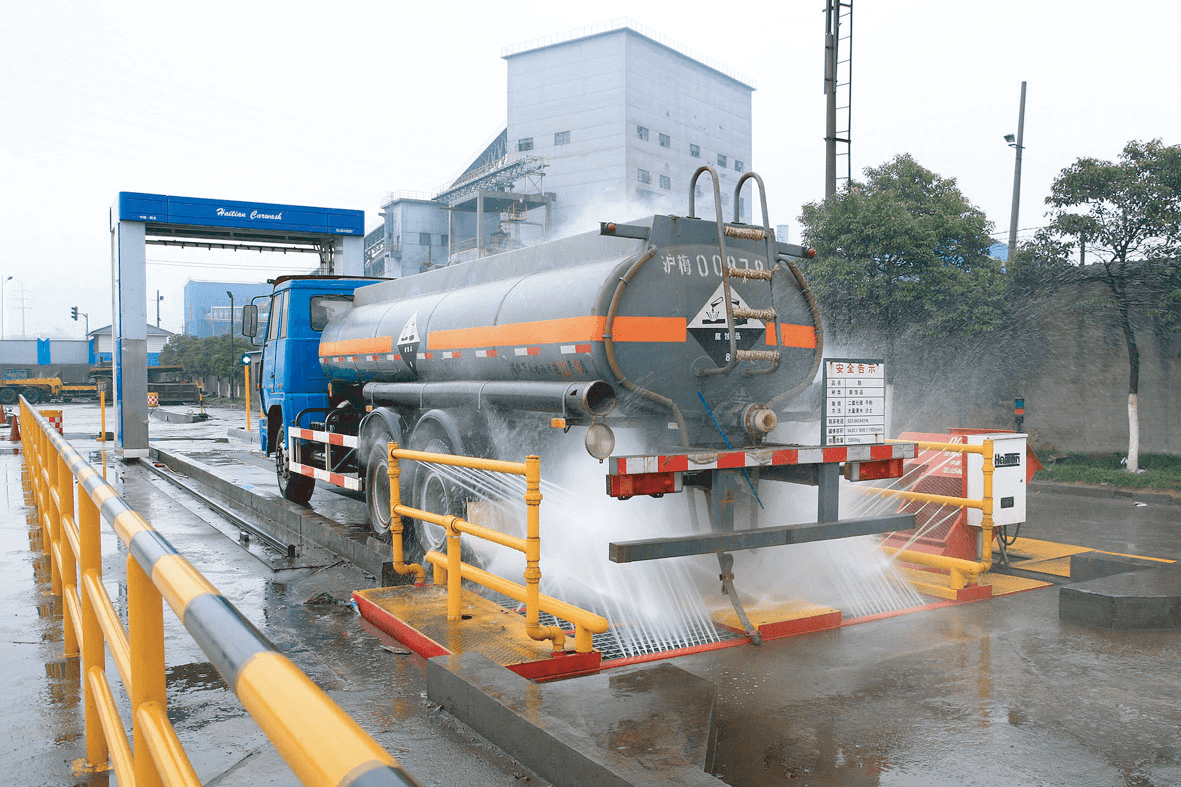

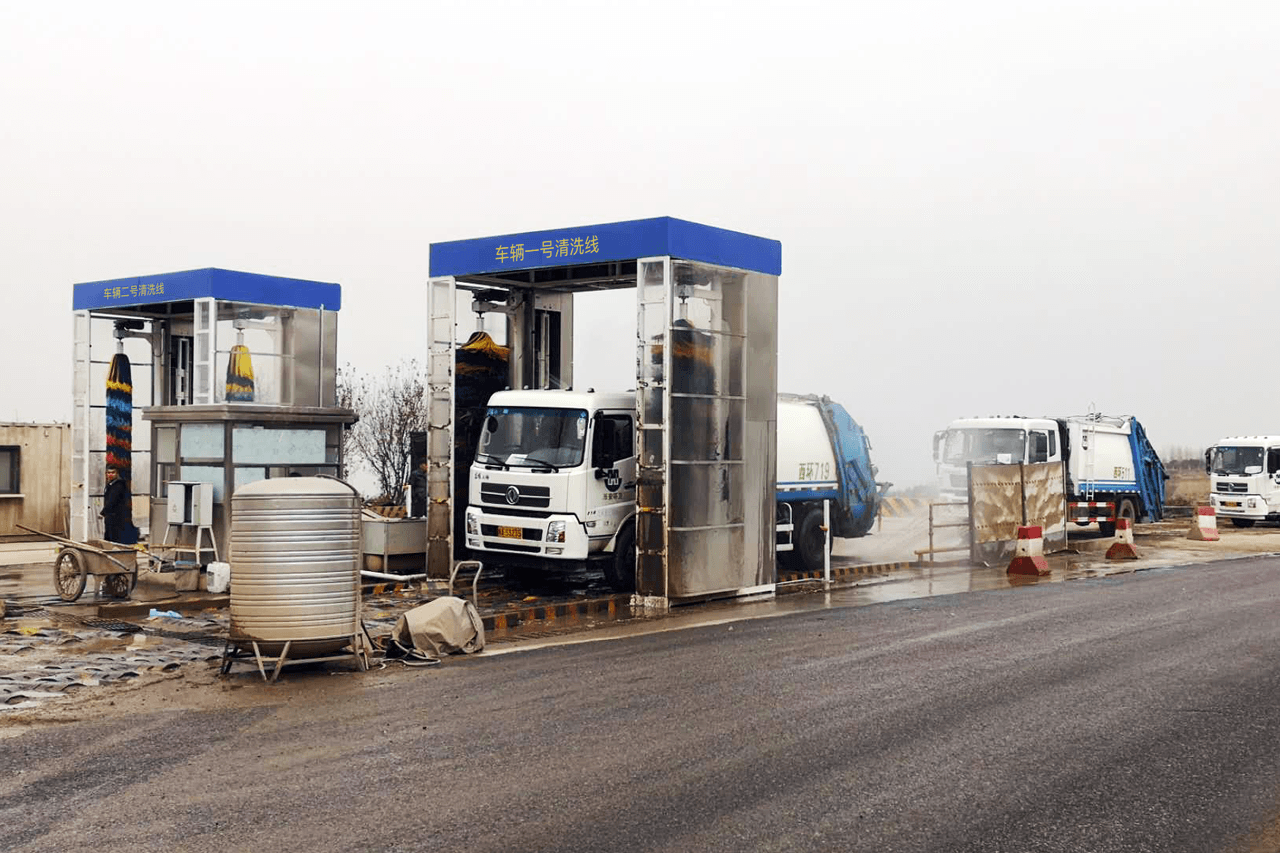

HyTian designs engineered-to-order wash systems for special fleets and industrial/municipal vehicles. We combine proven modules—brush packs, contour-following high-pressure arches, gantries or drive-through frames, chassis rinse, and high-efficiency blow-dry—to build complete wash lines matched to your vehicle profiles, soil levels, footprint, and throughput targets. Program libraries can be paired with license-plate recognition so each vehicle gets the right cycle automatically, and integrated water-recycling units help reduce fresh-water use and support environmental compliance.

Highlights

Built to Your Vehicles and Site

Proven Modules, Industrial-grade

Wash Smarter with Automation

Integrated Water Reclamation

Versatile wash options

Configure your line from a catalog of modules: chassis rinse, contour-following high-pressure, gantry or drive-through high-pressure, top brushes, side brushes, pass-through or reciprocating body cleaning, and powerful blow-dry with optional silenced or redirectable blower arrays.

Programmable logic & vehicle recognition

Expandable PLC-based control supports license-plate recognition, multi-program libraries, and data logging so you can align wash recipes with vehicle type, soil level, and operating policies and track utilization over time.

Integrated Water Reclamation

HyTian’s recycling/clarification systems with staged filtration, chemical dosing, ozone treatment, and automatic backwash integrate directly with wash lines to enable water reuse and manage odors in heavy-soil applications.

Fit for demanding industries

We engineer custom wash systems for waste-transfer and landfill exits, power plants, coal and steel facilities, material transfer ports, vehicle manufacturing plants, and metro/train depots—applications where standard equipment often falls short.